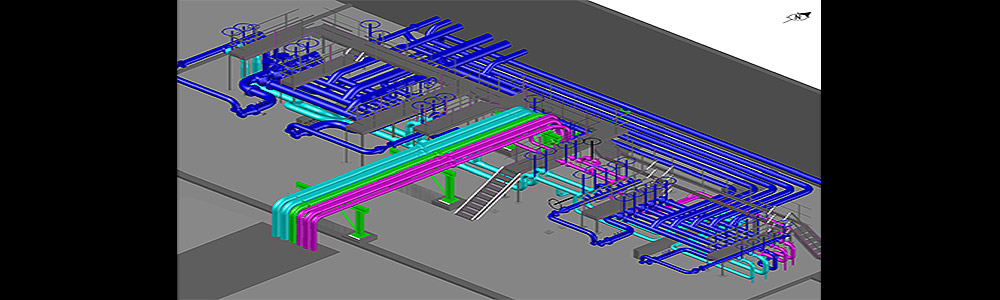

Terminals

Gekko has extensive experience working in marketing, storage, and shipping terminals. We have worked at land based and marine terminals for the largest companies in the world to smaller local owners. Our qualified multi-discipline engineering team has the expertise to assist with almost any terminal project. Whether dealing with tanks, piping, pumps, compressors, PLCs, or a truck rack installation Gekko can help ensure successful project implementation. A listing of Gekko terminal projects is included below.

Recent Project Examples

Produced Water Pipeline Replacement - Designed a new route for the relocation and material change of an existing 16" pipeline located underground in the center of a major street. Working with utility owners, Gekko obtained information of possible interferences which were used to determine the easiest and most cost effective routing option. Gekko coordinated with the city to permit the installation and provide safe traffic control plans for the construction.

Lateral Pipeline Modifications for Pigging - Gekko designed pipeline modifications of two valve vaults and modified portions of the pipeline at the terminal to allow the line to be pigged. Work included removal of a leaking valve and installation of MOVs in the client's terminal as part of a new mainfold to allow regular operations and pigging operations.

Wet Gas Slip Line Replacement - A 4000 foot section of an existing carbon steel wet gas was experiencing wall thinning required replacement. Gekko provided the solution design to slipline a 6" HDPE pipeline inside the existing 12" carbon steel line, which also adhered to DOT regulations. As the client's liason, Gekko coordinated with the county to obtain permits for investigative potholing and the sliplining construction. Additionally, Gekko coordinated on behalf of the client with SoCal Gas to obtain right of ways for a new valve box and tie-in to a Gas Metering Station.

Gas Gathering Line Installation - Gekko designed the installation of a new 10" carbon steel gas gathering line which routed from above ground going underground avoiding existing interferences back above ground to the tie-in. The new line was installed near a rail track at the port as such requiring railroad and port permitting.

Project ExamplesLateral Pipeline Modifications for Pigging - Gekko designed pipeline modifications of two valve vaults and modified portions of the pipeline at the terminal to allow the line to be pigged. Work included removal of a leaking valve and installation of MOVs in the client's terminal as part of a new mainfold to allow regular operations and pigging operations.

Wet Gas Slip Line Replacement - A 4000 foot section of an existing carbon steel wet gas was experiencing wall thinning required replacement. Gekko provided the solution design to slipline a 6" HDPE pipeline inside the existing 12" carbon steel line, which also adhered to DOT regulations. As the client's liason, Gekko coordinated with the county to obtain permits for investigative potholing and the sliplining construction. Additionally, Gekko coordinated on behalf of the client with SoCal Gas to obtain right of ways for a new valve box and tie-in to a Gas Metering Station.

Gas Gathering Line Installation - Gekko designed the installation of a new 10" carbon steel gas gathering line which routed from above ground going underground avoiding existing interferences back above ground to the tie-in. The new line was installed near a rail track at the port as such requiring railroad and port permitting.

- Produced Water Pipeline Replacement

- Comingling Multiple Lease Streams to Common Free Water Knockout Header

- Fire System As-Builts

- B31.4 Pipeline Stress Analysis

- NPDES Connection

- Radio Antenna Installation

- Tank Cathodic Protection Repairs

- Tank Conversion to Diesel service

- Stormwater Pump Replacement

- Biodiesel Blending Installation

- Fire Pump Upgrade

- Terminal Lab Upgrades

- Terminal Loading Rack PLC Upgrades

- Jet to Diesel Swap

- Ethanol Blending As-build

- Terminal P&ID Updates

- Pipe Lift Site Inspection & Evaluation

- Electrical Capstan Anchorage Design

- Electric Vault Inspection/Repair

- Berth Concrete Repair

- VRU Piping Misalignment Remediation

- PLC Drawing Conversion

- Thermal Oxidizer Installation

- Strainer Cap Pressure Capacity Evaluation

- Tank Farm Ramp Upgrades

- Terminal Ethanol Tank Conversion

- Pipeline Cathodic Protection System Power Analysis

- Degassing Technology Evaluation

- Terminal Area Classification Update

- Terminal Test Facility Upgrade

- TSV & Min Flow Bypass Program Evaluation

- Terminal Loading Rack I/O Upgrade

- TAS PLC Installation

- Terminal Diesel Pump Replacement

- Terminal UPS Replacement

- Terminal PLC Upgrade

- Terminal Fire Panel As-Built Update

- Terminal Lane Addition

- Ethanol Blending Demo

- Lab Drainage MOC Drawings

- Terminal Arc Flash Study

- Terminal UST Monitoring As-Built

- Terminal Tank Firewater Update

- Terminal Foam System Design

- Terminal Gasoline to Diesel Tank Swap

- Terminal Storage Rack Evaluation

- Terminal Pump and Blower Addition

- VR Line Drain & Pump S/D

- Terminal Diesel Lubricity Installation

- Terminal Canopy Extension

- Terminal Sump As-Built

- Terminal Warning Siren Installation